Zircon Rutile Ilmenite Sand Separating Plant includes spiral separators and shaking tables for efficient concentration, ensuring high-grade output. Customizable capacity with models ranging from 0.15-40 tons per hour. Supported by over 30 years of professional mining machinery expertise, this solution offers one-stop service from design to installation.

Description

Zircon Rutile Ilmenite Sand Separating Plant includes spiral separators and shaking tables for efficient concentration, ensuring high-grade output. Customizable capacity with models ranging from 0.15-40 tons per hour. Supported by over 30 years of professional mining machinery expertise, this solution offers one-stop service from design to installation.

Customer Stories

India 200 tons per hour zircon rutile ilmenite beach sand project

Beach sand main contents: Gold, Ilmenite, Rutile, Zircon, Tin, Hematite, Magnetite, Andalusite, Quartz, Corindone, Atlri, Garnet, Monazite, Tantalum&niobium etc.

Customer's target: remove magnetic minerals and get the high grade rutile, tin and Zircon, more important to high recovery gold ore.

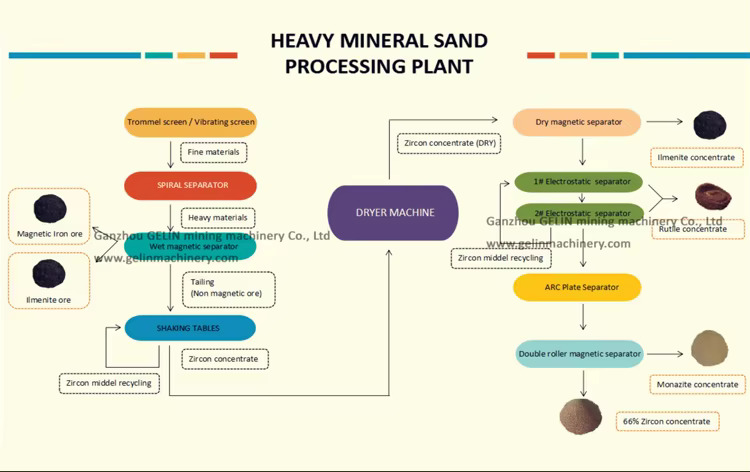

We design the processing flowchart as below:

1. Use sand pump feed material directly to spiral separator. If there are some bigger stones in deep areas, can consider use trommel screen to separate out particles +2mm

2. Spiral separator: use two-stages spiral separator, first stage is for rough concentration, the middling from first-stage will go to second-stage to concentrate again to get high recovery ratio.

3. Most of the heavy fractions are magnetic minerals, so in order to remove clean as much as possible, it is better to firstly use our factory special designed four rollers wet magnetic separator to remove magnetite ilmenite and hematite and weak magnetic ore.

4. the gold and zircon and other non-magnetic minerals goes to shaking table for concentration, also use two stages shaking table for getting higher concentration effect.

5. after the electrostatic separator, can get rutile and other minerals, maybe still including some magnetic minerals, so use a high intensity dry process magnetic separator to remove the magnetic minerals again, the zircon will be more high grade up to 66% for sale a good price.

We design different process flowchart depends on customer's actual mining condition.

Related Products