The three-rollers magnetic separator is mainly used for the selection and separation of titanium ore, chromite, garnet, quartz, feldspar, manganese ore, rare earth ore, niobium tantalite, limonite, chromite, titanium ore, zircon, monazite, rutile, garnet, andalusite and other excellent magnetic difference minerals, as well as the removal of iron purification operations.

Description

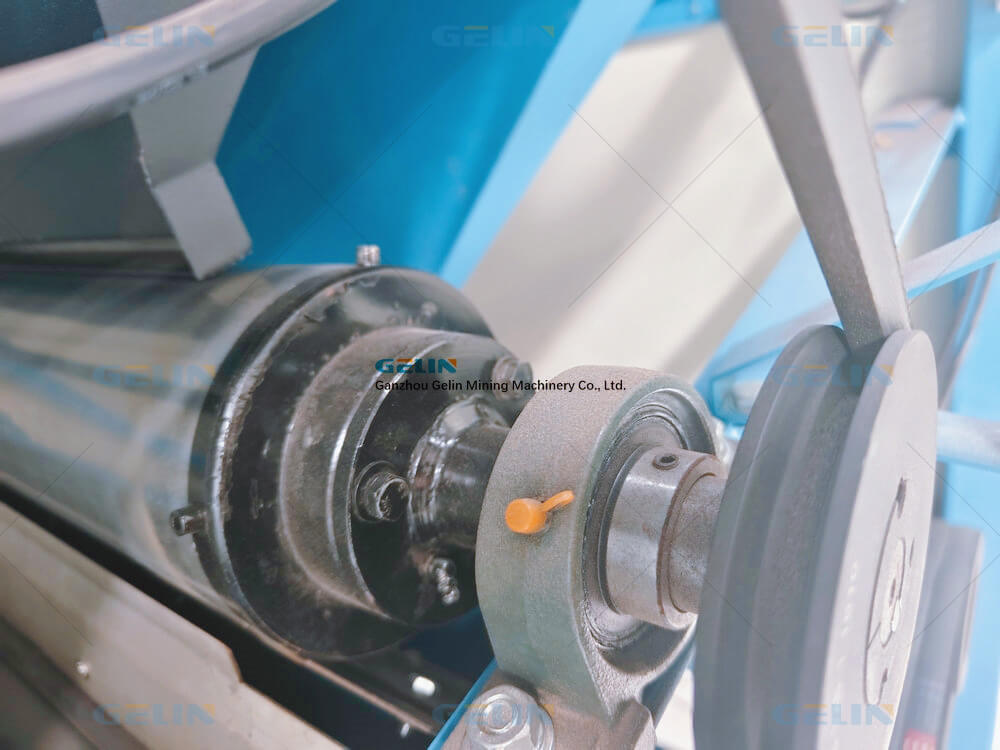

The three-rollers magnetic separator is made of the high-performance permanent material rare earth NdFeB by polymerization. The machine is a combination of upper, middle and lower rollers. The low magnetic field strength of the upper magnetic roller is 1000 gauss, which is used to separate strong magnetic minerals such as iron ore, and the medium magnetic field strength of the middle magnetic roller is 6500 Gauss, which is used to separate medium magnetic minerals. The lower magnetic roller has a high magnetic field strength of 10,000 gauss, which is suitable for the purification of weak magnetic minerals such as Monazite, and can achieve the magnetic separation of a variety of magnetic and non-magnetic minerals.

Specification

| Number of rolls | Capacity | Roller size | Material composition | Boundary dimension |

| 3 | 1-2tph | first roller: ╬”160*1040mm, 1000Gauss second roller: ╬”160*1040mm, 6500Gauss third roller: ╬”300*1040mm, 10000Gauss | the machine frame is made of steel with governor motor | 1570*1670*2560mm |

Principle

The magnetic separator is employed to effectively separate a diverse range of magnetic mixed minerals with particle sizes ranging from 0 to 2 mm. Based on the feasibility of magnetic separation, a primary magnetic roller is utilized for iron removal. Various combinations of magnetic minerals are selected accordingly. This machine is classified as having a downstream structure, based on the directional flow of both the magnetic products and the feed minerals intended for selection.

Detail Pictures

Related Products