Centrifugal concentrator is known as centrifuge or centrifugal chute, it is an efficient equipment for recovering free gold in all particle size ranges,specially for recovery of fine gold which is lost during the operation of the gravitational concentrators(sluice boxes and jigs). It can be used not only for placer gold mining, but also for recover the natural gold from hard rocks, to replace amalgamation and recover gold from the tailings.Application result shows that the recovery rate can be as high as 99%, and the concentrating ratio is up to 1,000 times. In recovering the natural gold in lode ore with size -0.074mm, the gold is up to 98%, For 0.004mm in particle size, the gold recovery is 97%.

Features:

1. High recovery rate: Through our test, the recovery rate for placer gold can be 98% or more, for rock gold, the recovery rate could reach 97% when the feeding size is below 0.04mm.

2. High efficiency: STLB60 Gold Concentration Separator has a capacity of 15-30TPH, and STLB100 Gold Concentration Separator has a capacity of 60-100TPH. Only one machine could give you such a high capacity and high recovery rate. It's the most efficient concentration equipment in our factory.

3. Easy to install: only a small leveled place required. It's a complete machine, before starting it, only need to connect the fluidization water and power.

4. Easy to adjust: there are only 2 factors that will affect the recovery result, they are water pressure and feeding size. By giving proper water pressure and feeding size, you could get the best recovery effect.

Easy to operate: after finishing the water pressure and feeding size adjust, what U have to do is to fetch the concentrates every 2-4 hours. (Depending on the grade of the mine)

5. No pollution: this machine only consumes water and electric power, and exhaust tailings and water. Low noise, no chemical agent involved.

6. Reliable: this Gold Concentration Separator gets a simple & tough structure, the main body is made by strong steel, and the concentrate cone is made by stainless steel. And the bearing is greased to keep it running well.

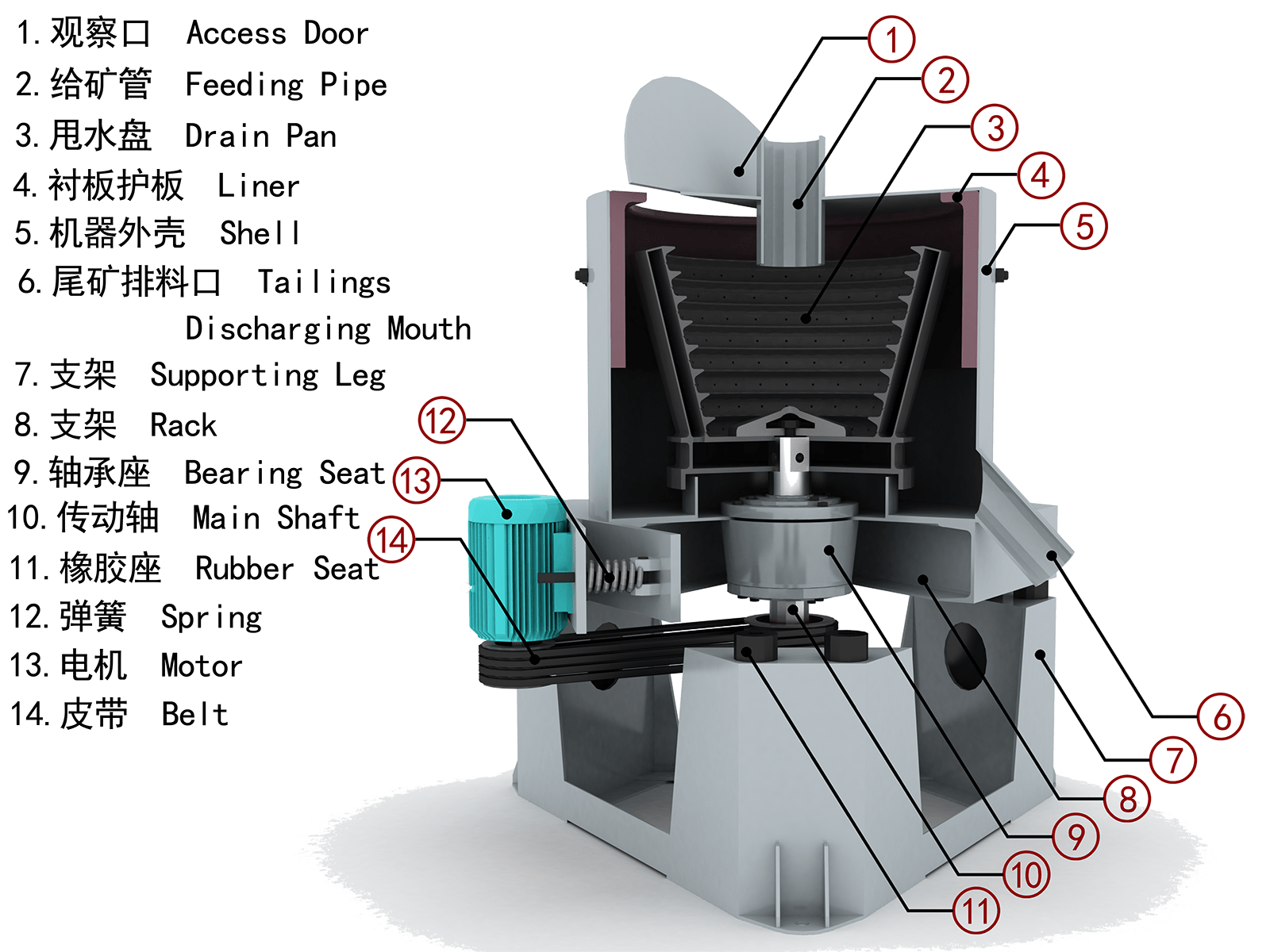

Structure & Working Principle:

During operation the lighter material flows upward over the grooves and heavy mineral particles (usually of economic value) become trapped within them.Pressurized water is injected through a series of tangential water inlets along the perimeter of each groove to maintain a fluidized bed of particles in which heavy mineral particles can be efficiently concentrated.

Parameter:

| TYPE | STLB20 | STLB30 | STLB60 | STLB80 | STLB100 | STLB120 |

| Capacity(T/H) | 0.2-0.3 | 2-3 | 10-15 | 35-45 | 60-100 | 80-120 |

| Particle size(mm) | 0-3 | 0-4 | 0-6 | 0-6 | 0-6 | 0-6 |

| Feeding concentartion(%) | 0-50% | 0-50% | 0-50% | 0-50% | 0-50% | 0-50% |

| Back wash water(T/H) | 1.5-2 | 4-6 | 10-15 | 17-25 | 50-100 | 100-120 |

| Output(kg/time) | 2-3 | 10-20 | 30-40 | 60-70 | 70-80 | 80-100 |

| Discharge cycle(H) | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 |

| Power (kw) | 0.75 | 1.5 | 5.5 | 11 | 15 | 30 |

| Rotary speed’╝łr/min’╝ē | 800 | 600 | 460 | 400 | 360 | 300 |

| Pressure water(Mpa) | 0.05 | 0.05-0.1 | 0.1-0.15 | 0.1-0.18 | 0.1-0.2 | 0.15-0.2 |

| Weight(T) | 0.25 | 0.5 | 1.2 | 1.5 | 2.5 | 3.2 |

| Approximately dimension’╝łmm) | 790X785X790 | 1180X1140X1250 | 1970x1670X1750 | 2300X1800X2200 | 2500X2000X2400 | 2500X2350X2500 |

Pictures:

Related Products