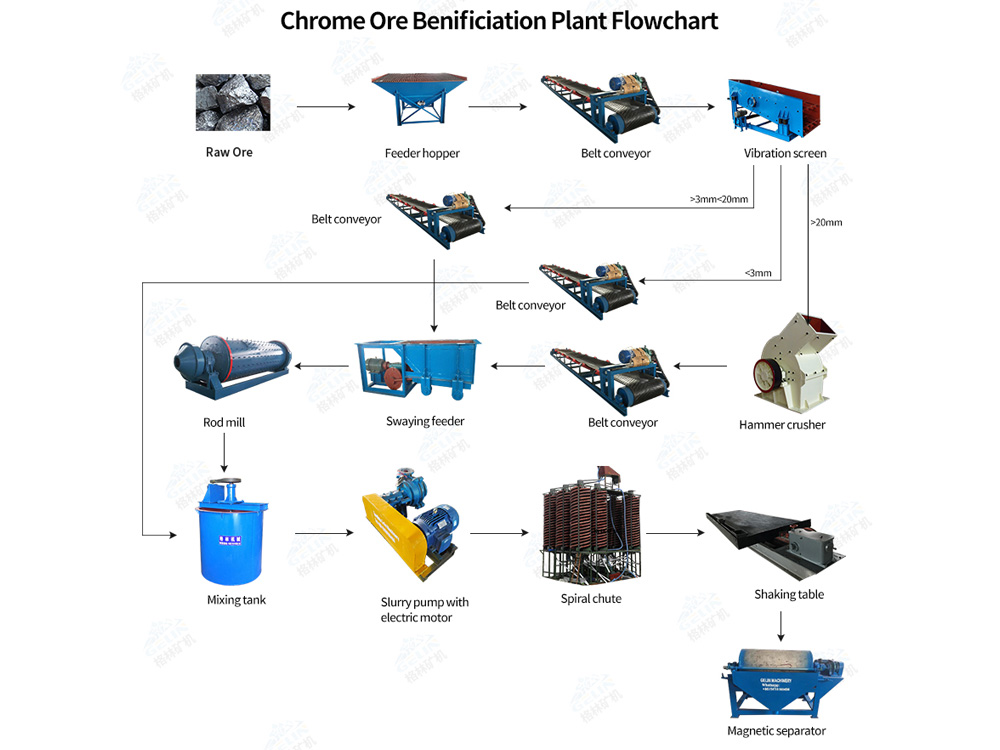

Chrome Ore Processing Plant mainly includes: Feeding->washing->sieving->primary gravity separation -> 2nd stage gravity concentration->magnetic separation for upgrading.

This is a Chrome Ore Processing Plant.

Chrome ore Feeding: can be vibration feeding machine, feeding hopper, belt feeder, wheel loader or excavator feed directly. Usually will make grizzly bar on vibration feeder or hopper to remove big waste stones firstly. Depends on process capacity to choose suitable chrome ore mining equipment.

Chrome ore Washing: the chrome ore washing machine is for washing clean the clay and mud in raw material, most popular used are chrome ore washing rotary scrubber and chrome ore washing trommel screen. Chrome ore rotary scrubber washer is for washing chrome ore raw material that with many sticky clay, chromite ore washing trommel screen is for wash chromite ore raw material that without much sticky clay. Depends on raw material conditions to choose suitable chrome ore washing equipment.

Chrome ore Sieving: after washing, then sieve out some bigger waste stones, the under screen slurry will go to next separation machine. This sieving process can use trommel screen or vibration screen or chrome ore high frequency vibration screen which is wided used chrome ore mining equipment.

Chrome ore Primary Gravity Separation: it is for primary chrome ore concentration process, jig separator or spiral separator are best choice of chrome ore gravity mining equipment. The concentrate ore discharged from them will send to 2nd stage concentration machine.

2nd Stage Concentration process: the concentrate ore from chrome ore jig machine or spiral spearator will go to chrome ore shaking table concentration machine for final concentration, can get high grade chrome ore concentrate. Shaking table is a good concentration effect mining equipment for chrome ore processing plant.

Related Products